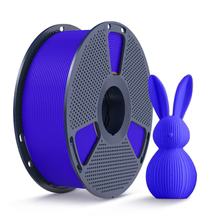

What do we print from?

PLA

01

PLA (polylactic acid) filament is a polylactide produced by converting starch to glucose, which in turn converts to lactic acid, which is then polymerized or polycondensed. Starch for PLA production is obtained from corn or sugar beets. The organic nature of the material makes it readily biodegradable, and its decomposition time depends on the additives used and can range from several months to several years. PLA is characterized by high biocompatibility, meaning it does not react with living organisms. This allows it to be used in medical applications. Traditionally, it is used to make surgical sutures, screws, and implants. The material is also widely used to produce consumer items that are designed for easy disposal.

PET G

02

PET-G (Polyethylene Terephthalate Glycol-modified with a glycol additive). PETG filaments combine the strength and flexibility of polyethylene terephthalate (i.e., "pure" PET, known for disposable beverage bottles) with the elasticity and reduced warping – the latter benefits are due to the glycol additive.

This material is impact-resistant and flexible, making it ideal for manufacturing parts that must withstand, for example, repeated mechanical loads. PET-G filament is also resistant to water and many chemicals, expanding its range of applications to include various components operating outdoors (a good example would be mobile exploration robots).

03

TPU

Thermoplastic polyurethanes (TPU) consist of an amalgam of diisocyanate and diols, which are polymerized to produce TPU. The diisocyanate is used to cross-link the diols, which act as the backbone chains of the polymer to provide the final product with flexibility and pliability.

TPU is also able to stretch and return to its original shape thanks to its extraordinary flexibility without causing any permanent damage to the item.

04

ABS

ABS stands for Acrylonitrile-Butadiene-Styrene. It is an impact-resistant thermoplastic containing an amorphous polymer. ABS is composed of three monomers: acrylonitrile, butadiene, and styrene.

- Acrylonitrile: This is a synthetic monomer. It is produced from propylene and ammonia. This component contributes to the chemical resistance and thermal stability of ABS.

- Butadiene: Derived from acetylene or by catalytic dehydrogenation of butane or butene, this component provides strength and impact resistance to the ABS polymer.

- Styrene: Produced by dehydrogenation of ethylbenzene, it provides stiffness and processability to ABS.

What are the structures of the plate?

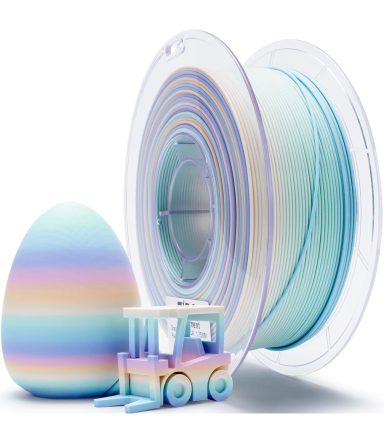

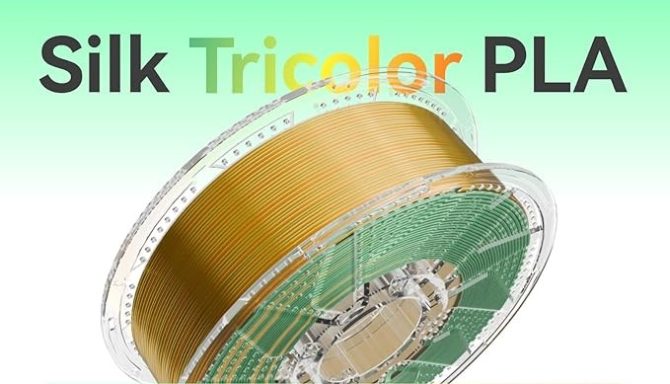

Colours of filaments:

If you are interested in a different color print, please send us a message.